This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

CLASSIFICATION, STORAGE AND ORDER PREPARATION USING MAGNETIC INDUCTION CONVEYING SYSTEMS

Download case study

Goals

Use of a simulation model to validate the design of a new material handling system regarding orders preparation.

Sector

Medical

Results

Study of different ways of preparing orders. Tool to support daily operative to choose the best resources configuration. Justification of the investment.

Development

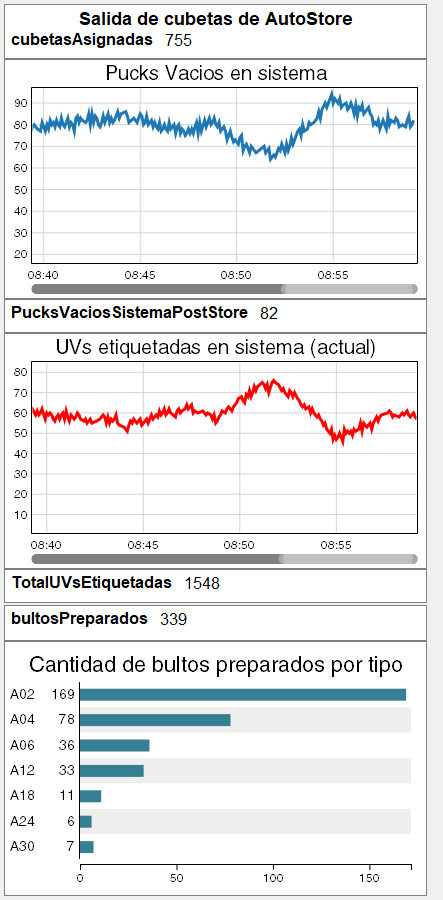

Working side by side with the client, the development of the model was fast and succesful as it was being built and validated simultaneously. Therefore, once the 3D environment was created, all the logic were defined: AutoStore entry and exit, product labelling, wrapping, reprocesses, routings of products, etc.

Analysis & Results

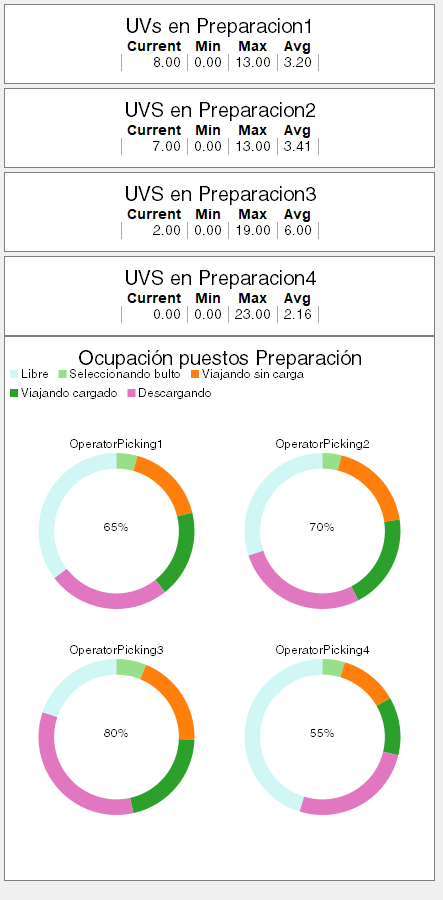

When it comes to the analysis, the key objective of the model was to maximize the completed orders in a fixed time, trying to minimize the total length of the MagneMotion transporter used until the picking stations, taking into account breakdowns and availability of machines.

Background

In one of the plants of a company which produces surgical compo nents, it was needed to improve efficiency of an order preparation area . As the system was in the design stage, the use of a simulation model which allows to validate the material handling system involved in it known as MagneMotion, s et the operation logic of the orders preparation and choose the config uration parameters of the process becomes really useful. Thus, by using FlexSim simulatio n software, a model is built to test different kinds of preparation ways by analysing the main parameters invo lved in the process (number of preparation s tations, vehicles needed to tra nsport products, maximum content of the loops…).

Conclusions

This simulation model can be used to get the best configuration of the operation parameters of the system giving the order schedule of each day. Furthermore, it a lso represents an useful tool that has helped to validate the design of the system proposed by the supplier and justify the big investment that it is involved in a risk free environment

Sucessful Case

How to analyze the design of a new material handling system? What logic of operation is the best? How many resources are needed?

Simulation system

Intralogistic